Optimised process sequences, modern drawing machines and the use of the latest annealing and surface technologies

CLAAS and KLINCKE stand for centuries of wire making tradition* in Altena. This tradition has been continued by the Falz family since 1989. They first acquired the company Max W. Claas GmbH & Co. KG, and then, six years later, Hermann Klincke J. H. Sohn GmbH & Co. KG. Today, CLAAS/KLINCKE wire factories are two independent companies that are at the cutting edge of technology and ecology.

...

CLAAS/KLINCKE-wire factories

Competent. versatile. unique.

Max W. Claas GmbH & Co. KG was rebuilt at the Grünewiese site between 2008 and 2013 and was expanded with 3,000 m2 in 2018. In 2023, with the addition of another 3,000 m2 of hall space for the annealing shop, drawing shop and administration, Hermann Klincke J. H. Sohn GmbH & Co. KG positioned itself as a future-orientated company. Optimised process sequences, modern drawing machines and the use of the latest annealing and surface technologies form the basis of wires made with high quality standards. The exceptional production spectrum with wires featuring diameters of 0.50 – 50 mm, short throughput times, maximum reliability, individual delivery units, large storage areas, product-oriented solutions and fully covered logistics centres are just a few examples of the efficiency of CLAAS/KLINCKE wire factories.

Synergies create new capacities

The synergies resulting from the close co-operation between the two companies are unique and generate production plant buffers in all areas of production. Both companies are certified in accordance with IATF 16949, DIN EN ISO 14001, ISO 45001 and DIN EN ISO 9001. With four pickling lines, CLAAS/KLINCKE wire factories have an impressive capacity at their disposal. Three modern hood annealing lines featuring HICON®-H²-annealing technology, fully automatic programme sequence, 8 sockets, 4 heating hoods, 4 cooling hoods as well as automated CQI-9 annealing processes and base capacities of 65 t achieve spheroidization degrees of up to 100 % and guarantee repeatable microstructure properties.

In 1738, a total of 19 wire rolls were listed in the “Specifikation der bey der Freyheit Altena befindlichen Drahtmühle“ as “auf der Rahmeder Bache” by the mayor, Johann Moritz Goecke. This includes the "Rolle unter der Heyde", which was managed by Johann Adolf Claas from 1846. The "Winne vor der Brücken" (later also referred to as "Rolle an der Lenne" and "Schinder-Rolle"), the "Grosse Rolle vor der Brücke" and the "Rölleken vor dem Teiche" were located on the site of today's KLINCKE wireworks. The latter were acquired respectively by Johann Hermann Klincke and Friedrich Wälzholz in 1837 and 1841.

...

CLAAS/KLINCKE Products

Cold heading wire

For the production of fasteners and cold extruded parts with demanding requirements for cold workability. Optimum conditions for the material structure, surface finish, geometry and mechanical properties.

Through-hardening rolling bearing wire

For the production of rolling elements such as needle rollers, balls and other roller elements. Use of ingot and continuous cast material from exclusively certified pre-material suppliers.

C-Wire

Quality steel wires for the manufacturing of sophisticated products that are produced by bending, heading, rolling or tooling. Infinitely variable C-range from 0.02 % to 0.95 % is available.

Tool steel wire

For the manufacturing of high-quality tools such as screwdriver blades, angle screwdrivers, drills, punches, chisels, knives and extrusion tools. Cr-alloyed, V-alloyed and Mo-alloyed variants with extremely good forming properties.

Heat treatable spring steel wire

For the production of springs with special properties. Cr-alloyed, V-alloyed and Mo-alloyed variants. Design with the highest possible degree of moulding.

...

CLAAS/KLINCKE Industries

CLAAS/KLINCKE wire factories supply companies around the world in the field of automotive, joining and forming technology and tool and rolling bearing industries. The unique production range of wires with diameters of 0.50 – 50 mm is impressive.

...

CLAAS/KLINCKE Goals

Focus on responsibility and foresight

CLAAS/KLINCKE wire factories will continue to invest in new production processes, employee training, consistently high-quality standards, customer-orientated delivery capability and a growing portfolio of products. Flexibility, reliability, responsibility and foresight characterise the management of both companies. Securing customer contacts, supplier relationships, jobs and the careful use of resources are of fundamental importance. Total quality management (TQM) and a continuous improvement process (CIP) are an integral part of the corporate philosophy.

...

Quality assurance and quality maintenance

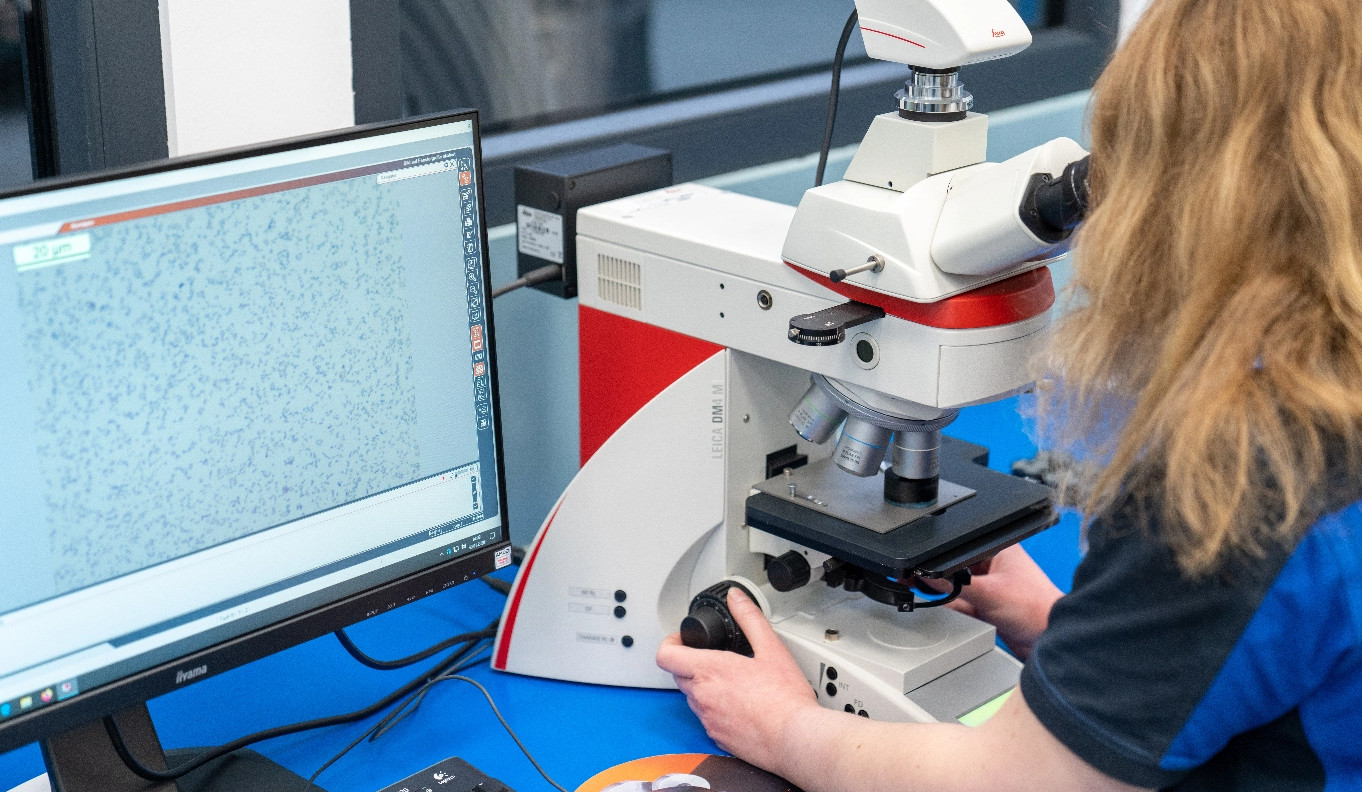

CLAAS/KLINCKE wire factories manufacture cold heading wires, rolling bearing wires, tool steel wires, spring wires and C-wires with diameters of 0.50 - 50.00 mm with high standards of quality and reliability. Quality assurance and quality maintenance are at the heart of quality management. Both companies are certified in accordance with IATF 16949, DIN EN ISO 14001, ISO 45001 and DIN EN ISO 9001. The use of the latest generation of production systems ensures consistently high quality. State-of-the-art measuring and testing systems form the basis for seamless documentation. A 2,000 kN tensile testing machine is available to determine the mechanical properties of the wires and offers the possibility of analysing wires with a diameter of up to 50 mm with regard to tensile strength, constriction at fracture, elongation at fracture and yield strength. Other testing and documentation options include metallography, metal analyses, magnetic particle crack detection and the measurement of roundness, hardness and roughness.

...

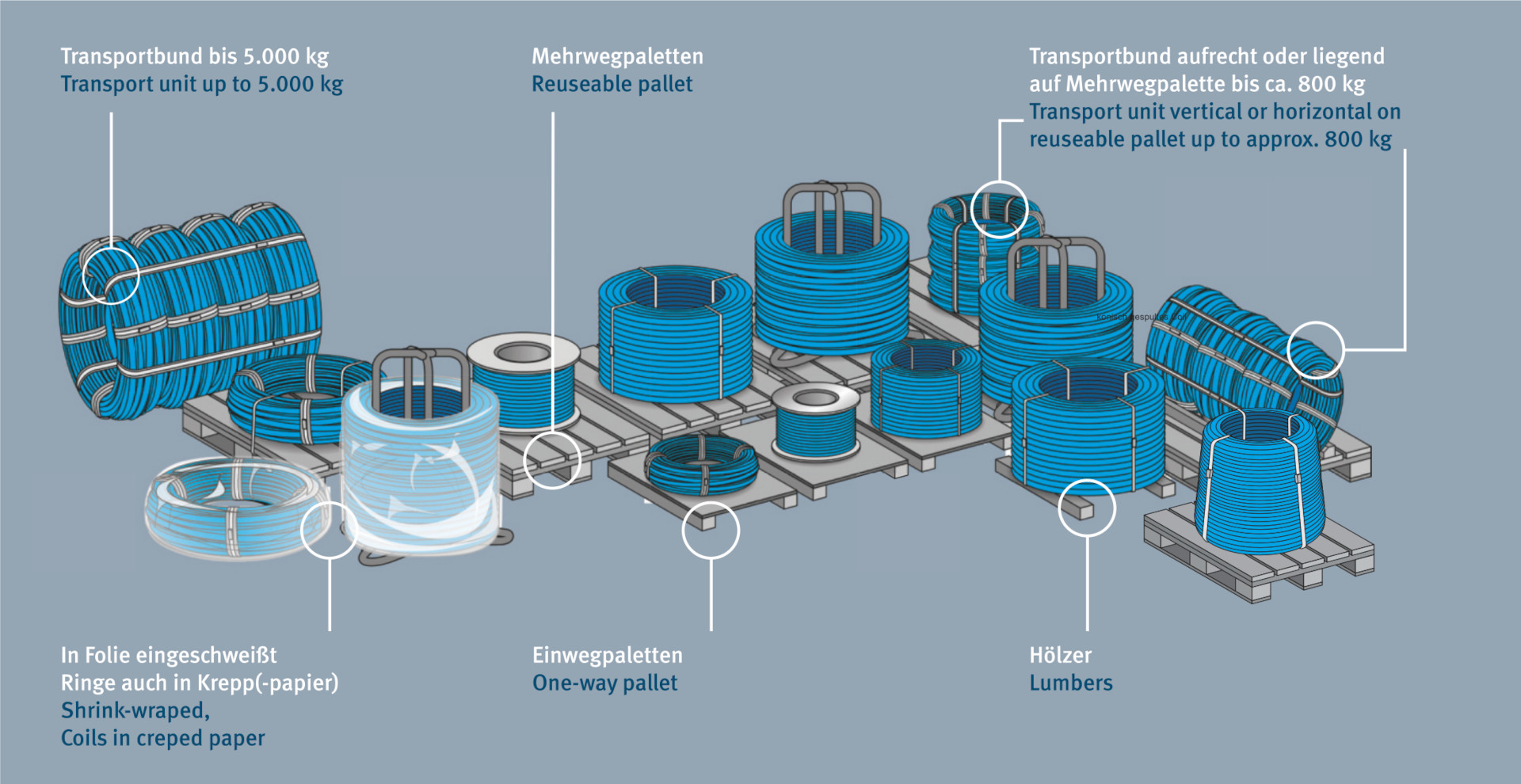

CLAAS/KLINCKE Service

With a high level of consulting expertise, customer-specific solutions, optimised wires and short throughput times, Max W. Claas GmbH & Co. KG and Hermann Klincke J. H. Sohn GmbH & Co. KG offer a unique, full service. Customised product packaging such as crown stands, cylindrical/conical coils, plastic spools, rings, transport bundles up to 6,000 kg, reusable pallets, disposable pallets, wood and much more demonstrate the customer-oriented way of thinking and acting. Experience the efficiency of CLAAS/KLINCKE wire factories!